elco customer solutions

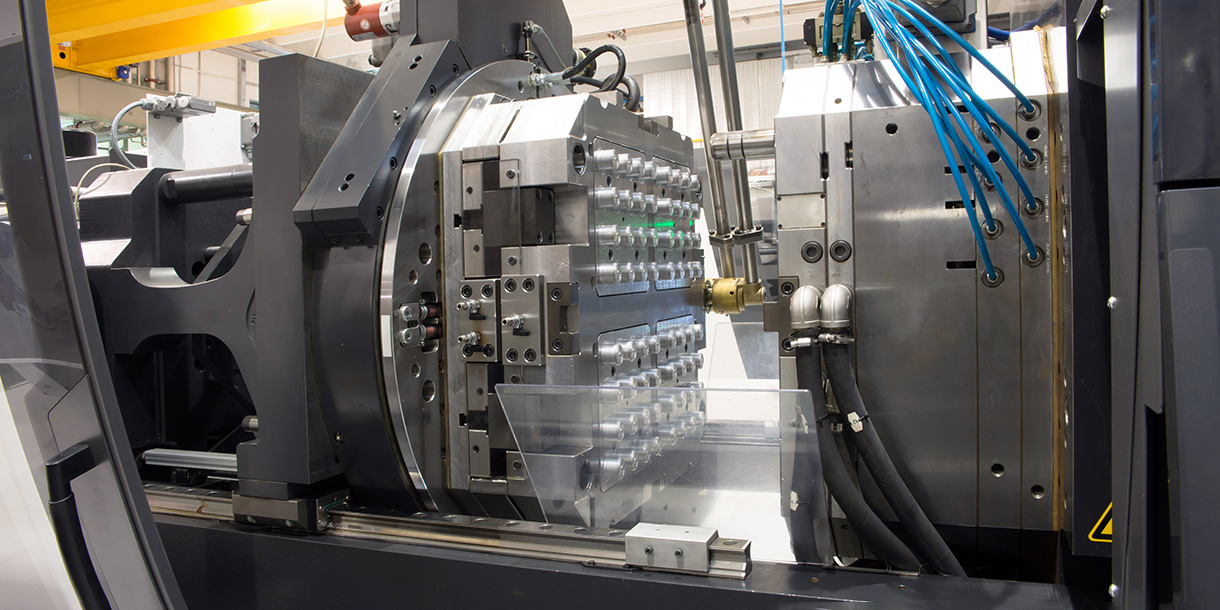

Do you have an idea of your own? Our developers can provide you with comprehensive advice on product design, optimum materials and efficient production methods so that you get a clear-cut and economically viable concept from your idea.

Satisfied elco customers

© 2024 ELCO KunststoffeWebdesign by MEDIUM Werbeagentur