The long-standing successful collaboration with reputable brand suppliers demonstrates one of ELCO’s major strengths: customer-specific product development and manufacture.

In this process, you not only profit from the pooled expertise and experiences of our team, but also from the ELCO philosophy, which puts the focus on customer success. We are not happy until you are inspired. You can look forward to a companion with designated contact persons, who is fully committed to supporting you in every step of the way until you reach your goals.

Consultation

Do you have an idea or very concrete ideas already? Depending on your needs, our developers provide you with comprehensive and holistic advice on product design, optimum materials and efficient production methods so that you get a clear-cut and economically viable concept from your idea.

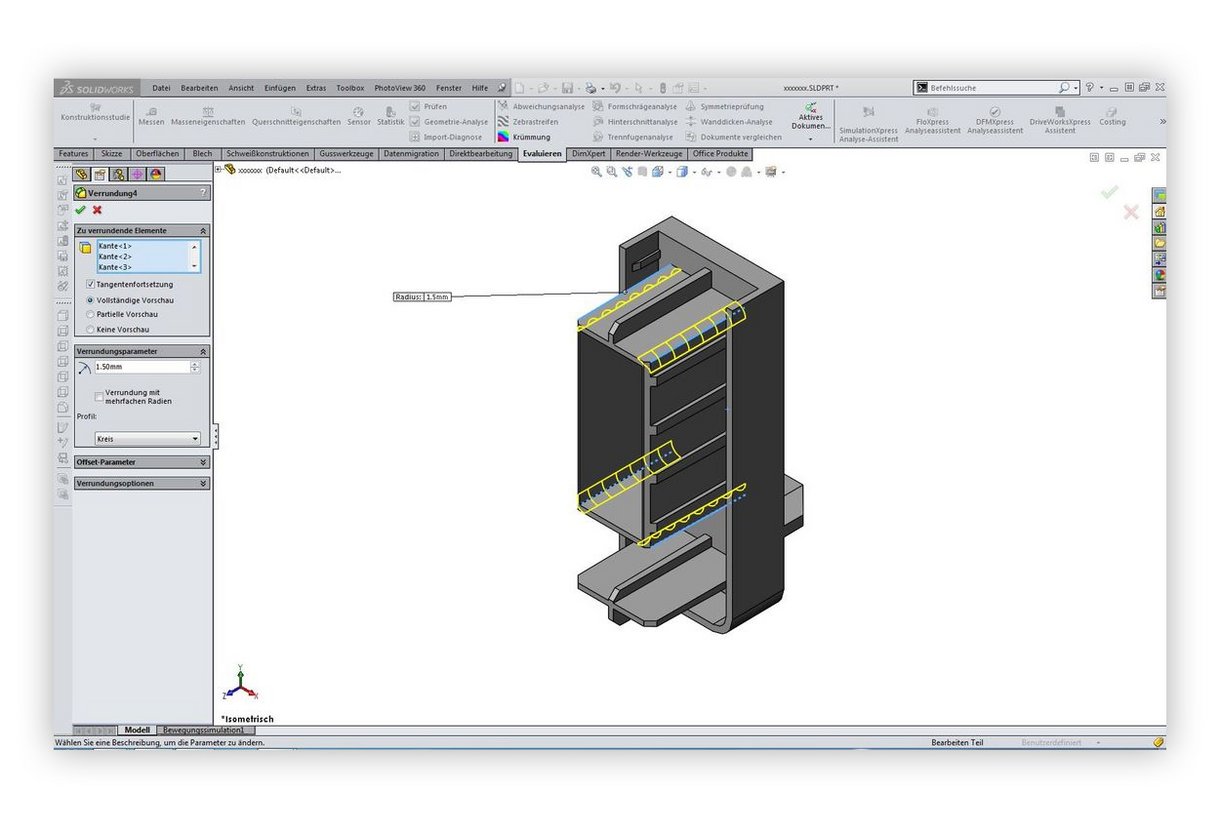

Design

Some customers come to us with complete design data, some with a model or prototype, and some only with an idea. Each case is perfectly fine with us. Depending on the current stage, we start on the pre-production process, employing our technology and expertise. We create, read or optimise 3D design data so that product development can be visualised and we can obtain an optimum data pool for tool making.

Prototypes

Our longstanding experience in prototyping and prototype production allows us to quickly provide you with a concrete and tangible result, which in most cases is vital for evaluation and further processing.

We use the following techniques for this: stereolithography, laser-sintered parts, casts made from silicone moulds, aluminium tools and 3D printing.

Tool conception

For series production in the areas of thermoforming, injection moulding and extrusion, we design and develop high-precision tools which, with workshop maintenance, meet the highest standards for the future and ensure production safety.

Production, assembly, packaging and delivery

Our production utilises tried and tested methods in our versatile machine park and is characterised by a high level of standardisation and stable processes as a result.

At the same time, modern assembly and packaging techniques such as ultrasonic welding, hot plate welding, bonding and printing guarantee a high degree of customisation to satisfy your requirements.

We tailor ourselves to your entire business throughout the whole process, down to implementing packaging requirements and delivering exactly as required. You can rightly expect more from us than mere production according to your specifications. ELCO is the modern process partner with whom you can achieve innovative plastics solutions for your market success.